March 5th 2025 10:26:27 AM

Scanco’s MVP Release: The Power of Cutting-Edge Functionality with Acumatica

May 8th 2024 15:24:54 PM

We are thrilled of the coming release of Scanco’s MVP-connected solution. A solution that will revolutionize warehouse management. As an MVP release, this is just the beginning of an incredible journey toward a more efficient and thriving warehouse ecosystem. Meet the exciting lineup of functionalities. Here are the tools you can expect in the MVP.

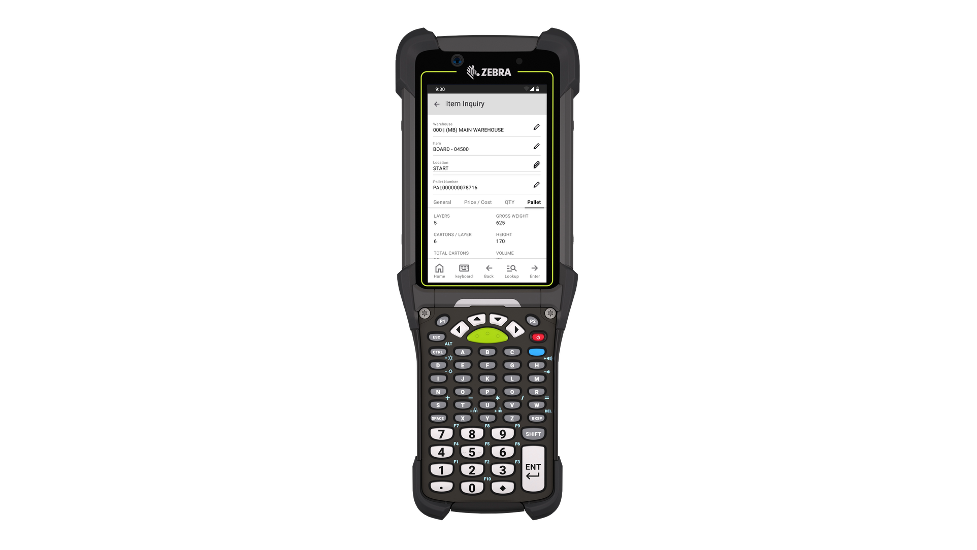

Item Inquiry

The power of real-time visibility and comprehensive insights into your inventory. Seamlessly integrated with the Acumatica ERP system, this invaluable tool empowers users to make more informed decisions, optimize operations, and enhance overall efficiency. Easily access critical data such as item descriptions, stock levels, locations, pricing, etc. With Item Inquiry, you’ll know how to conquer any inventory challenge that comes your way

Warehouse Transfer

This tool is designed to streamline inventory movement within your warehouse network, ensuring accurate tracking and efficient transfers between locations. Whether you’re fulfilling customer orders, replenishing stock, or consolidating inventory, Warehouse Transfer simplifies the entire process. Experience seamless inventory control and witness the power of optimized storage space and improved stock allocation.

Physical Count

Eliminate discrepancies and maintain an unwavering level of integrity in your inventory records. Conduct efficient and accurate physical inventory counts, reconcile discrepancies, and keep your financial reporting on point. With Physical Count, you can confidently navigate compliance requirements, reduce disruptions, and gain full control over your inventory valuation.

Picking (Single, Wave, Batch)

Maximize the efficiency and accuracy of your order fulfillment process. Whether you’re handling individual orders, high-volume waves, or consolidating multiple orders, our Picking functionalities have got you covered. Seamlessly pick items one order at a time with Single Picking, optimize routes, and increase productivity with Wave Picking, or leverage the power of batch processing for small, lightweight items with Batch Picking: experience faster order processing, reduced errors, and unparalleled customer satisfaction.

Receiving

Enhance the efficiency and precision of your order-receiving process. Whether receiving individual items, handling high-volume shipments, or consolidating multiple deliveries, our Receiving functionalities have covered you. Seamlessly document and verify incoming goods one item at a time with Single Receiving, streamline the processing of large shipments with Wave Receiving, or efficiently handle small, lightweight items in batches with Batch Receiving. Experience faster goods receipt, reduced errors, and unparalleled inventory accuracy with Scanco’s Receiving module for Acumatica integration.

Directed Put Away

Directed Put Away (DPW) is critical in Scanco’s warehouse management strategy. By strategically assigning storage locations based on item attributes and demand patterns, DPW optimizes inventory placement and streamlines warehouse operations. It reduces unnecessary movement, minimizes picking and replenishment times, and enhances inventory accuracy. DPW also enables efficient warehouse layout design, ensuring accessible items and improving overall productivity. With DPW, Scanco can maximize efficiency, minimize errors, and provide faster order fulfillment.

Packing (Single, Wave, Batch)

Scanco offers three packing methods – Single, Wave, and Batch – to optimize the order fulfillment process. In Single packing, each order is packed individually as soon as it is ready for shipment. Wave packing combines multiple orders into a single wave order. Batch packing involves consolidating similar products from different orders into a single batch. With these versatile packing options, Scanco streamlines the order fulfillment process and increases operational efficiency.

Printing & Labels

Printing is essential in warehouse operations and enhances inventory management. Scanco enables businesses to generate and print barcode labels to track items efficiently throughout the warehouse. These labels can be customized to include vital information such as item name, SKU, location, and pricing. By accurately labeling items and their respective storage locations, Scanco ensures easy identification and reduces picking errors.

License Plating

License Plating is a powerful feature offered by Scanco. With License Plating, Scanco assigns a unique license plate number to a group of items, such as a pallet or container, for easy tracking and traceability. This enables efficient movement of goods within the warehouse, simplifies picking and put-away processes, and enhances inventory accuracy. By consolidating items under a single license plate, Scanco optimizes space utilization and reduces errors.

Custom Allocations

Custom Allocations help optimize inventory allocation and improve order fulfillment efficiency. With Custom Allocations, Scanco enables businesses to define specific rules and criteria for allocating inventory to orders. This allows for greater flexibility and control in determining which items are assigned to each order based on priority, location, or customer requirements. By tailoring the allocation process to individual business needs, Scanco helps optimize inventory utilization and reduce picking errors.

Scanco is excited to announce several upcoming features this year that will revolutionize your workflow, such as Work Center Replenishment, Cross-Docketing, cutting-edge AI capabilities, and more!

With Scanco, you don’t have to deal with the hassle and complexity of traditional warehouse management systems. Warehouse management tools can easily integrate with Acumatica ERP systems with Scanco’s MVP without lengthy implementations or complex integrations.

To learn more about Scanco’s Acumatica Warehouse Automation, visit our website.

Reach out to us to discover the ideal solution tailored to your company’s needs. Connect with us online or give us a call at (330) 645-9959.