Manufacturers and Distributors Benefit from Warehouse Automation

Manufacturers and distributors focus on decreasing costs while increasing efficiency…

“With the quality of the data I’m getting, my allocations are dead right every time. And our profit margins have improved because of the new process paired with Scanco’s barcoding system.”

Jack Buhr

ACCOUNTANT, CLIFTON MOULDING CORPORATION

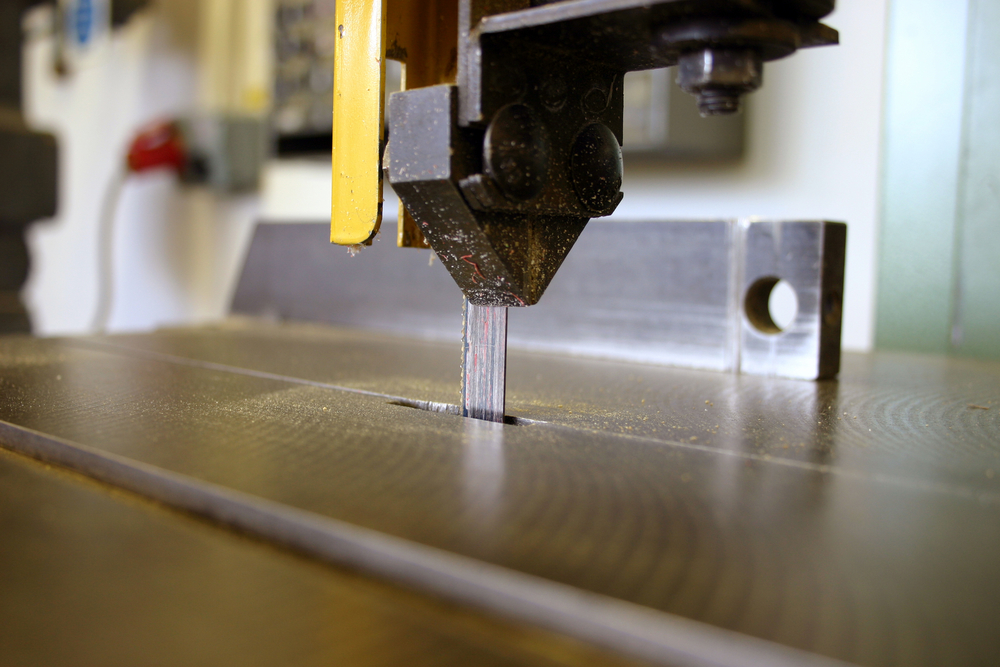

Clifton Moulding Corporation was founded in 1957, and has been under current ownership since 1991. They manufacture primed, finger-joint, and solid mouldings in Clifton, TX. With a staff of 130 dedicated mill workers, utilizing a 200,000 square foot facility and a combination of well-maintained legacy equipment as well as state of the art CNC equipment, they produce a high quality product.

When faced with an opportunity to grow profitability via improved usage of their planer with rough lumber, the team knew there was no way they could take on the challenge without some improvement to back office and inventory processes.

For many years, Clifton had operated their planer at a low volume using hand tags: Planed lumber was run through the machine once more and produced SKUs that were manually keyed into the database.

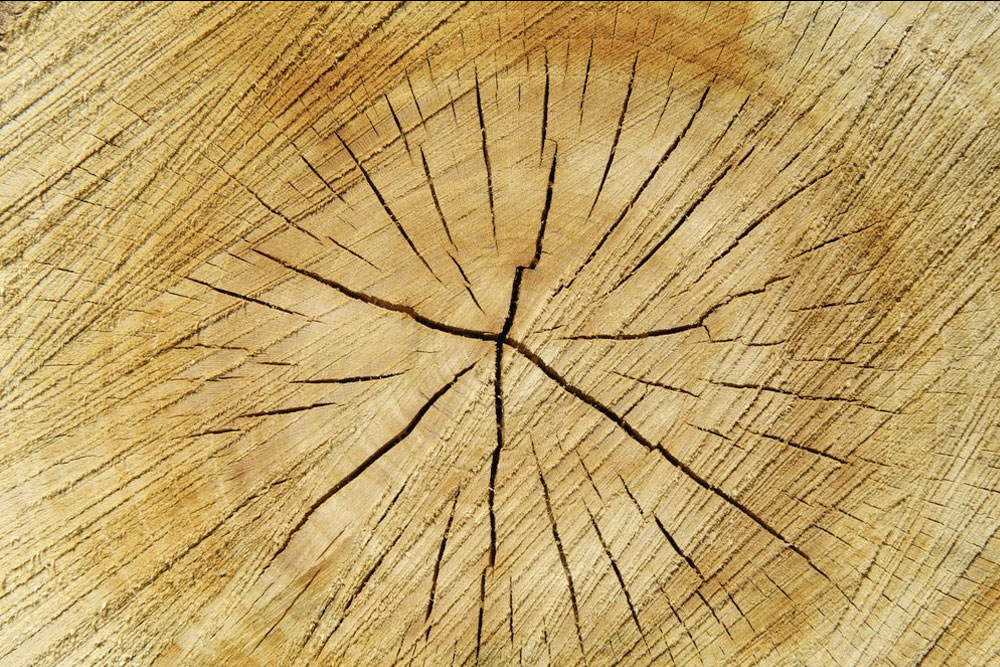

When an opportunity arose to work with a mill that would send Clifton an alternative raw material, Jack Buhr, who oversees Clifton’s IT processes, knew they had a great opportunity to effectively utilize technology to provide necessary transparency. “The more we can do inside of our plant, the more we optimize our use of material,” said Buhr.

This raw material ultimately allows larger profit margins for Clifton, and a considerably more complex SKU volume. “It becomes a four-step process in the warehouse for us with multiple SKUs for each material,” said Buhr. “Without a robust barcoding system, it would be impossible to take advantage of this opportunity.”

Another challenge was finding a solution that would integrate with the mill’s current ERP solution. “We use Sage 100 and did not want to change,” said Buhr. “I reached out to our Sage consultant, Beth Bowers, and she said Scanco was the best solution, hands down, so I figured I wouldn’t look any further.”

It was important to have a barcode solution that worked intuitively with Sage 100 and was easy for the employees on the shop floor to adopt. “Our company has grown because of a great team of people that have worked here forever. We love our people and knew that changing their processes had the potential to disrupt things.”

Fortunately, the Scanco solution was flexible and easy to use right out of the box. “We put a lot of thought and heart into decisions and changes,” Buhr said. “Implementing Scanco was easy, largely due to the clean and intuitive interface. Our team took ownership of the new process because Scanco wasn’t frustrating or hard, which is exactly what you hope for with a new system implementation.”

With the new Scanco barcode inventory solution, Clifton could build their system on WIP versus finished SKUs. Now every time a SKU is created out of the planer, it is tagged and results in an inventory transaction and receipt. An inventory issues is then created as a WIP SKU goes back through the planer and creates another inventory receipt, and on and on.

The new barcoding process is easy and intuitive for the employees on the shop floor. Tasks are straightforward, including scanning inbound inventory, creating a tag, and tagging the outbound inventory, all with reliable and durable handheld scanners. “I didn’t want the technology to get in our employees’ way. They are exceptionally skilled at running planers and grading material. I wasn’t trying to make them into technicians. And Scanco doesn’t get in their way.”

Everyone at Clifton is benefiting from the new barcoding solution. “We love the fact that you never have to touch a keyboard with Scanco,” Buhr said. “All data is collected in real time. We provide inventory reports to our manufacturing team every morning. They have a clear picture of the workflow which makes their job much more efficient and easier to manage. Scanco has set our team up for success.”

Scanco’s barcode data keeps Clifton’s accounting accurate. “We pay a fixed price for raw material, and we want to allocate that cost based on the value of what we got out of that log,” Buhr noted. “If we put $1 worth of material into the planer, we only want to account for only $1 coming back out. With the quality of the data I’m getting, my allocations are dead right every time. And our profit margins have improved because of the new process paired with Scanco’s barcoding system.”

Overall, Clifton Moulding made a great business decision when they implemented the new barcoding solution. “Why Scanco? Because the data integration is perfect,” Buhr concluded. “This software lets me maintain my business process. The data flow is very reliable. The interface on the shop floor is manageable, and the hardware holds up.”

We understand there’s not a “one-solution fits all” option for complex distribution and manufacturing operations. We want to learn more about your business and understand the challenges that you are looking to overcome.

Schedule a short conversation with a Scanco Solutions Expert today. Give your team the tools to pick and ship orders fast: from Warehouse Automation to Manufacturing Automation. Get more done while making fewer mistakes by eliminating unnecessary manual tasks.

DOWNLOAD RESOURCES

Looking for more information on Scanco’s solutions and services? Check out our online resource page. Its filled with solution data sheets, white papers, customer success stores and, more.

PRODUCTS

Want to learn more about the products used in this case study? Check out our Sage Warehouse Management Page

Fill out the form to gain access to all Scanco resources.