SAGE 100 MANUFACTURING AUTOMATION

TAKE CONTROL OF YOUR OPERATIONS.

MAKE DECISIONS WITH CONFIDENCE AND SPEED.

Manufacturing Automation for All Types of Operations

Connect everyone and everything in order to drive production, quality control, and improve productivity.

Automate job management functions and gain real-time insights into the workflow.

Sage 100 Manufacturing Software Modules

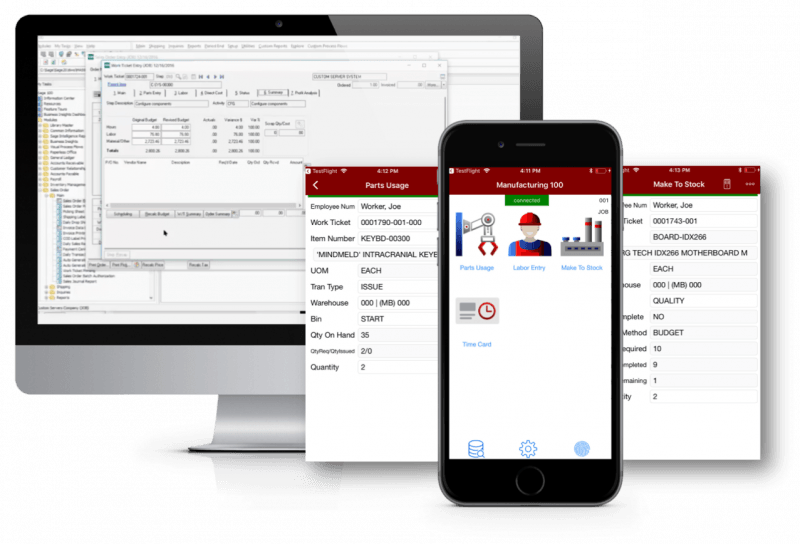

SCANCO MOBILE MANUFACTURING APPS

MANUFACTURING 100

Manufacturing 100 is the leading mobile manufacturing app for Sage 100

Manufacturing 100 LITE

Cost-Effective Barcode Tracking

Manufacturing 100 LITE eliminates manual data entry tasks, delivering immediate access to accurate, up-to-date information. Capture your Work Order transaction data on the shop floor in real time with handheld devices.

Manufacturing 100 LITE includes many of the same capabilities as the full system such as Material Issues, Labor Tracking, Status Updates, MultiBin capability, and Timecard.

Compare Features

MANAGE FINISHED GOODS FOR INVENTORY PROCESSES

Manufacturing 100 is the perfect solution for manufacturers that are looking to maximize efficiency. Eliminate manual tasks by incorporating mobile scanning and automation across all your warehouse operations.

This barcode data collection system adds even more functionality than Sage Shop Floor for tracking Material Issues, Labor Tracking, Status Updates, Finished Goods Entries, and Time Card. All data are validated real-time and go directly into Sage 100.

Manufacturing 100 is available for iOS and Android-enabled devices. Scanco Solution Specialists can help you decide which handhelds will be perfect for your production environment.

Advanced manufacturing automation for complex operations

Manufacturing 100 is the most comprehensive solution available for Sage 100.

It brings advanced functionality to Sage Production Management including allowing alternate parent items.

Working with Operations Management (JobOps), it can automate job management functions for complex manufacturing operations.

With countless hardware accessory options, users can scan barcodes, look up items, and send counts real time into Sage.

Recommended Hardware

Compare Features

SAGE 100 MOBILE MANUFACTURING AUTOMATON FEATURES COMPARISON

-

MFG100 LITE

| |

MODULE |

$2195/yr |

| |

USER LICENSE |

$195/yr |

| |

|

|

| Materials |

Issue Materials on Work Ticket |

X |

| |

Issue Non-Work Ticket Materials |

|

| |

Review Transaction before import |

X |

| |

Display Qty Remaining |

X |

| |

Allow Exceed Quantity Required |

X |

| |

Allow Negative Quanitiy issues |

X |

| |

Track Employee |

X |

| |

Allow Multiple Warehouses |

X |

| |

Advanced Item Inquiry |

|

| |

Work Ticket Picking |

|

| |

|

|

| Labor |

Clock In/Out on Work Ticket |

X |

| |

Change Work Center |

|

| |

Change Activity Center |

|

| |

Change Status Code |

X |

| |

Record Quantity Completed |

X |

| |

Review Transaction |

X |

| |

Auto Track Out |

|

| |

Auto Send to Sage |

|

| |

Labor Dilutions |

|

| |

|

|

| Completions |

Review Transaction |

X |

| |

Filter Tickets by Work Ticket Class |

X |

| |

Track Employee |

|

| |

Print Labels |

X |

| |

Material Completion by Item |

X |

| |

|

|

| Status |

Record Status Change |

X |

| |

Review Transactions |

X |

| |

Track Quantity Completed |

|

| |

Default Quantity Completed |

X |

| |

Track Comment |

|

| |

Default Status Code |

|

| |

|

|

| Time Card |

Clock In/Out for Payroll |

X |

| |

|

|

| Multi-Bin |

Compatibility |

X (MBS) |

| |

|

|

| Dashboard |

Standard Configuration |

|

| |

Personalized Configuration |

X |

| |

Read Only |

X |

-

MFG100

| |

MODULE |

$4595/yr |

| |

USER LICENSE |

$395/yr |

| |

|

|

| Materials |

Issue Materials on Work Ticket |

X |

| |

Issue Non-Work Ticket Materials |

X |

| |

Review Transaction before import |

X |

| |

Display Qty Remaining |

X |

| |

Allow Exceed Quantity Required |

X |

| |

Allow Negative Quanitiy issues |

X |

| |

Track Employee |

X |

| |

Allow Multiple Warehouses |

X |

| |

Advanced Item Inquiry |

|

| |

Work Ticket Picking |

|

| |

|

|

| Labor |

Clock In/Out on Work Ticket |

X |

| |

Change Work Center |

X |

| |

Change Activity Center |

X |

| |

Change Status Code |

X |

| |

Record Quantity Completed |

X |

| |

Review Transaction |

X |

| |

Auto Track Out |

X |

| |

Auto Send to Sage |

X |

| |

Labor Dilutions |

X |

| |

|

|

| Completions |

Review Transaction |

X |

| |

Filter Tickets by Work Ticket Class |

X |

| |

Track Employee |

X |

| |

Print Labels |

X |

| |

Material Completion by Item |

X |

| |

|

|

| Status |

Record Status Change |

X |

| |

Review Transactions |

X |

| |

Track Quantity Completed |

X |

| |

Default Quantity Completed |

X |

| |

Track Comment |

X |

| |

Default Status Code |

X |

| |

|

|

| Time Card |

Clock In/Out for Payroll |

X |

| |

|

|

| Multi-Bin |

Compatibility |

X (MBS/MBP) |

| |

|

|

| Dashboard |

Standard Configuration |

|

| |

Personalized Configuration |

X |

| |

Read Only |

|

LEARN MORE

Let's Chat!

Are you ready to take control of your production costs? Talk to one of our solutions experts about Sage 100 manufacturing automation.