Manufacturers and Distributors Benefit from Warehouse Automation

Manufacturers and distributors focus on decreasing costs while increasing efficiency…

By improving efficiencies and cutting costs, automation technology is one of today’s fastest-growing supply chain innovations available for Sage ERP users.

Distributors are facing more challenges than ever before in today’s constantly changing world of warehouse management. Emerging trends in retailing and complex global supply chains are putting more pressure on distributors and manufacturers to increase output, cut costs, and reduce inventory cycles. Companies like Amazon have entirely changed the way retailers do business adding even more pressure with customer expectations of “next-day” and even “same-day” shipping. Distributors must find new ways to solve challenges more effectively.

Management also has countless responsibilities to worry about as well, such as:

If all of this sounds like a lot, that’s because it is. Zebra listed all these factors and more as drivers of change in the warehouse marketplace. In short, your job is not only tricky but may be getting more difficult every year.

To compete in this dynamic environment, today’s warehouses must be proactive and responsive. That means implementing new improvement strategies to gain critical efficiency gains, reduce costs, and maximize productivity. More and more warehouses are looking at automation to help them achieve these objectives but, what is warehouse automation and how exactly can it help?

We’ve put together this comprehensive guide to outline the many aspects of warehouse automation that you should know – and some best practices for implementing automation successfully.

From warehouse robots to barcode scanning, people have a very different idea of what warehouse automation is. Warehouse automation encompasses a wide range of technologies that promise to increase warehouse productivity by leaps and bounds. At its core, though, automation revolves around identifying repetitive tasks that are process-oriented, time-consuming, or error-prone, and finding ways to automate them.

Warehouse Automation can be broken up into two main categories: Process Automation and Physical Automation.

Process Automation – digitizes manual processes like physical inventory and integrates that data into your software environment, such as your Sage 100 ERP system. Process automation runs on an ecosystem of barcoding and wireless barcode scanners to input and tracks data at the point of activity, which communicates back to your ERP system.

Physical Automation – includes various forms of mechanized automation and refers to the use of robots and robotic systems in the warehouse. Its more costly to implement, and only provides a reasonable ROI for larger high-volume warehouse and distribution center (DC) operations. Physical automation includes goods-to-person (GTP) technology, driverless automated guided vehicles (AGVs) and Autonomous Mobile Robots (AMRs).

While process and physical automation are robust, choosing the right type of automation for your company can make the difference between a successful implementation or failure. The trick is to not buy into automation until you establish a solid business case for change based on your business’ needs. While there is no single “best” solution for everyone, there is one “best” solution for your business.

Your warehouse occupies a critical role in your business’ supply chain. As a core hub of logistics, your warehouse is not just a back-end operation that stores goods, materials, or inventory. It’s a critical link essential to the success of your supply chain it’s connected.

Problems and delays in your warehouse operations can be attributed to outdated, manual processes. The outcome isn’t only errors and delays but is practically guaranteed to hurt the company’s bottom line.

If we know inefficient processes can have downstream consequences, that means the reverse is also true. Warehouse automation, efficiency gains created in the warehouse can be passed on, driving improvements in the rest of the organization and supply chain.

Distributors that introduce automation technologies in their warehouse often experience several of the following benefits:

The ability to support new manufacturing applications that improve profitability and customer service, such as Production Management and Inventory Resource Planning (IRP)

As you can see, the benefits of what automation provides in the warehouse can easily extend beyond the loading docks, warehouse aisles, and shelves. It can create a ripple effect throughout the organization, improving efficiency in the shop floor, on the production line and in-field service dispatch, and mobile sales reps.

How do you know if your organization is ready to deploy automation?

Before we look at when you should, let’s look at some of the myths around warehouse automation that might prevent you from considering it:

Myth: Automation is an inflexible strategy that will put a stranglehold on my logistics operations, with no way back.

Truth: If an in-depth analysis is done beforehand, risks can be minimized or eliminated.

Myth: Automated systems are costly and out of my investment scope in terms of ROI

Truth: Using these systems has a direct impact on an installation’s profitability.

Myth: These rigid solutions are out of touch with my core business activities

Truth: Today’s advances in technology offer a broad range of solutions are available on the market for all sorts of sectors and warehouses.

Warehouse automation is not as big, scary, or costly as the myth-makers make them out to be. If you are experiencing one or more of the following symptoms daily, it’s time to look into warehouse automation:

Automating a warehouse, particularly a warehouse once operated entirely manually, is a serious undertaking, but one that pays off in dividends when automation is evaluated, analyzed, and planned.

Automation at its core revolves around identifying repetitive tasks that are process-oriented, time-consuming, or error-prone, and finding ways to automate them. Also, as anyone in the warehousing industry knows, warehouses are rife with repeatable, process-oriented, and error-prone tasks, ranging from manual documentation errors to picking and stocking errors, shipping and receiving errors, and much more.

For this reason, there are many aspects of warehouse operations that can be automated, including:

What are the steps to consider when getting started with automating your warehouse?

Traditionally in warehouses, data is collected is through handwritten notes on paper or manually entered or re-entered data entry. This data is stored on a spreadsheet or an existing legacy database. As you can imagine, it’s not the most efficient or reliable method, and yet a vast majority of warehouses still use physical processes.

Perhaps the most significant demonstration of the effectiveness of automation is in receiving activities.

For example, when a shipment arrives at your warehouse, employees inspect each box or item on the pallet, they write down or type in the SKU and quantity, before being stored in bins. Each time your employee enters a SKU, amount, or any other type of information, there’s a possibility of human error, such as a re-ordering of numbers. Now that error is recorded, and in the “data-base” it can impact an entire order, as incorrectly captured data for that material is binned, transferred, picked, packed and then shipped.

In this example a customer could potentially end up with the wrong product altogether because the “1” that was mistaken for a “7” on the SKU represents a different item, setting off the costly return process. You also run the risk of a dissatisfied customer. It will significantly affect your reputation among vendors and consumers.

That’s just 1 SKU!

Automating the data collection process, removes the opportunity for human error, significantly reducing the chance that the item will be improperly received, stored, transferred, picked, packed, or shipped to the customer.

Your inventory data is only as good as the quality of the information you collect. Now that your data is collected with maximum accuracy through automation, it’s time to put it to use for inventory control. Inventory management allows the product data captured in receiving to be updated in real-time as inventory transactions take place.

For example, employees can scan products in receiving, automatically capturing data at the receiving dock. Another employee scans the bin where the stock will be stored. All these movements and activities are tracked in a WMS. It knows where to find the inventory and how much is on-hand in those particular bins. Transfers are also captured and stored.

Because all the movements of the items were captured by mobile scanners, when it comes time to pull that inventory for an order, the picker has an exact count of that stock. Once picked, the items are scanned, and the quantity updated with the handheld scanner. Again, these transactions are sent to Sage in real-time.

In addition to updating the remaining inventory levels, your shippers have the right product in the right amount; it is then sent to the customer. Also, managers can now see that the newly pulled items have caused the level of stock to fall below the re-order threshold. Having accurate counts, managers don’t have to guess or take chances, let alone risk an inconvenient stockout.

The definition of a WMS, or Warehouse Management System, is a software platform that takes over and automates your internal logistics to make intelligent, real-time decisions that direct your worker movements through the warehouse with maximum efficiency. WMS helps you control and tracks the movement of materials in your warehouse, but with far more functionality and operational flexibility. WMS software provides a high level of control and resource utilization tracking for product movement and storage in and around your warehouse.

Developed out of the realization that warehouse employees spend a significant chunk of their time walking around the warehouse. Employees can spend up to 60% of their time trying to locate items. That’s just on task. Your warehouse team also spends time commuting to-and-from locations during receiving, putaway, restocking/replenishing, and fulfilling orders. Looking at your daily maintenance tasks, such as trying to find space for incoming products, moving stock around and cleaning/reorganizing, and it becomes clear how many opportunities there are to lose out on efficiency.

Warehouse management software can streamline time-consuming tasks by directing warehouse processes like picking, putaway, and replenishment. A WMS will also optimize activity paths that cut out unnecessary movement and minimize the time it takes to perform each action. Combined with the ability to direct and validate inventory transactions as it flows through the warehouse, WMS solutions have the potential to provide significant gains in efficiency, productivity, and cost-cutting.

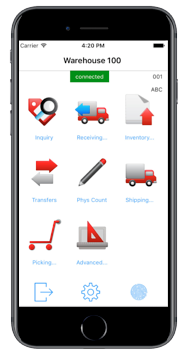

Choosing a WMS solution requires some homework. One can quickly be taken down the road to an expensive and resource-heavy solution. For most companies, a simplified WMS alternative is an option. These solutions can offer much of the core functionality of a full WMS but, without the complexity, expense, or upkeep. Products like Scanco Warehouse & Multi-bin can be deployed rapidly without intruding on existing infrastructure, connects directly to your Sage ERP, and offers an ROI in months instead of years.

Regardless of your choice, it’s essential to also have a thorough project plan in place before moving forward. Implementing a WMS can be complicated. It requires close integration with existing warehouse processes and workflows. Also, your warehouse needs to remain up and running at full speed while any new system is tested, integrated, and deployed. At least until your team has had a chance to learn the new system, like any form of change management, an effective plan can make the difference between implementation success or failure.

Today’s distributors and manufacturers need integrated information. Customer orders, inventory, shipment, and visibility of incoming products or inventory is crucial. However, most find themselves using several disconnected management systems. Each is providing the ROI to the intended area, but these disconnected systems make it challenging to meet more significant fulfillment challenges. Connecting these silos of automation is the key to an efficient operation.

Scanco’s mobile automation and WMS solutions integrate with your Sage 100/100 system bringing down those walls of isolation. This integration delivers a seamlessly integrated ecosystem that is fully transparent to all the players involved — from the suppliers of raw materials, components, and parts, to the transporters of those supplies and finished goods, and finally to the customers demanding fulfillment.

The integrated Sage and Scanco “technology stack/bundles” of automation technologies deliver robust functionality like integrated planning and execution, logistics visibility, smart procurement, and warehouse/manufacturing automation even spare parts management.

Additional integrated benefits include:

Scanco solutions are designed to help distributors and manufacturers manage their inventory, manufacturing, and picking processes as quickly and accurately as possible with minimal additional setup.

Scanco automation and WMS solutions extend your Sage account delivering inventory and warehouse management features that enable users to track information in detail—allowing you to manage inventory and warehouse transactions better. Harnessing the power of mobile apps and mobile devices, Scanco solutions work with your existing processes and warehouse setup. Scanco automation and WMS helps improve inventory accuracy and reduce the time spent searching for and handling items in your warehouse. Scanco multi-bin and WHSE enterprise dashboards guide users through warehouse processes to perform essential tasks, from receiving and storing items to picking and shipping them. As your worker’s process items in the warehouse, each transaction entered updates Sage data records in real-time.

Scanco solutions are designed to help distributors and manufacturers manage their inventory, manufacturing and picking processes as quickly and accurately as possible with minimal additional setup.

Let’s take a look at some of the Scanco Automation and WMS solutions for Sage.

Automating your warehouse processes can give you back time. Time that can be used in other areas of your business. Plus, automation software saves you the administrative task of updating Sage, and you can utilize the time to expand and promote your business.

A warehouse management system (WMS) ensures that you know where your product is at all times by using multi-bin features and incorporating barcode scanning to record inventory and other warehouse activities. Combined, they not only improve your accuracy but also enhance and optimize your warehouse operations.

The decision to deploy a warehouse automation solution often represents a step-change in overall business performance, allowing you to take charge of inventory, fulfill accurately, and lower operational costs. Unfortunately, distributors incorrectly assume that the cost of purchasing automation solutions outweighs the immediate or long-term benefits. In the final section of this guide, we will help shed some light on justifying warehouse automation from a return on investment (ROI) standpoint.

In general, the successful implementation of a warehouse automation solution can reduce operational costs by 10 to 40%. Let’s say you’re a consumer goods company with $3million in revenue. This cost represents 2-3% of your sales (on avg. 10-15% of sales rev is allocated toward logistics costs), then this reduction in warehouse costs can add as much as 2- 3 percentage points to your bottom line!

It doesn’t seem like much, but when you add up the dollars on $3 million in annual sales, that’s $60,000!

Some guidelines to consider when developing your ROI calculations:

There are some things to consider when focusing on the ROI as the main driver for purchasing a solution. ROI can sometimes place too much emphasis on a narrow set of financial benefits.

Identify a set of KPIs considered critical to your long-term business success. Examples of these KPIs include:

For Example:

Consolidating all your inventory into a central warehouse may appear to be a logical choice for reducing your freight costs while taking advantage of economies of scale. However, while the ROI of consolidating demonstrates big cost improvements financially, strategically the effort of consolidating to one warehouse may actually impact ROI in a negative fashion.

Taking a strategic approach, you may find that by improving order fulfillment, inventory and warehouse practices, with simple automation solutions, without moving warehouses has a faster, direct impact on business. By automating and improving your order fulfillment activities, accounts receivables look better and delivery times significantly improve. All this leads to higher customer satisfaction which ultimately improves shareholder value and, cash-to-cash cycle time.

For the warehouse manager or 3PL who is not primarily responsible for inventory levels, keeping operating costs such as labor under control while maintaining customer service levels may ultimately take a higher priority as an ROI condition. Luckily, most inventory reduction efforts usually come hand-in-hand with operating cost savings.

If you are interested in doing a complete ROI analysis, you can contact Scanco and we’ll help you determine the potential savings generated from a modern WMS. We’ll also share some results from other operational benefits to help you with the analysis.

ROI and Benefits of a successfully installed automation or WMS solution:

To succeed, distributors of any size must think big—to meet the diverse needs of customers while maximizing efficiency. Scanco automation and WMS solutions can get you there.

Scanco can help propel your businesses forward. For over 28 years distribution companies have gained operational efficiency through automating manual processes with our solutions. They’re increasing operational visibility and tightening processes using mobility-based data collection and process automation.

Our best-in-class, industry-focused applications can help you take control of your most pressing challenges and pain points. Our full suite of applications for wholesale distribution—from planning and procurement to warehouse management—deploy modularly and work together seamlessly with your Sage ERP. Scanco applications also use a standard data model that offers a single source of truth. With this end-to-end suite for wholesale distribution, you’ll have the tools you need to lower operating costs, differentiate products and services, and maximize profits.

We hope that you have found this guide to be informative, and we look forward to starting a conversation with you about Scanco’s automation and WMS solutions for Sage.

Fill out the form to gain access to all Scanco resources.